Technology Information Sheet

Granular Activated Carbon

June 2004 Fact Sheet 2004-06

What is Granular Activated Carbon?

Granular activated carbon is a highly adsorbent material used to remove contamination from water. Granular activated carbon particles are commonly used in municipal and home drinking-water filter systems to remove odors, taste, and excess chlorine. Carbon also is used to treat contaminated groundwater. As water passes over the carbon, contaminants stick to the surface of the particles.

Granular activated carbon is manufactured from materials with a high carbon content such as coal, wood, coconut shells, or walnut shells. It is "activated" by heating it to increase the amount of surface area, giving contaminants more surfaces on which to adhere. The surface area of one pound of activated carbon is equal to 125 acres.

What is Tailored Granular Activated Carbon?

Part of the surface area of each standard granular activated carbon particle is positively charged. This surface area attracts negatively charged contaminants, such as perchlorate, in a way that is similar to iron being attracted to a magnet. However, because the positively charged surface area of standard carbon is limited, using standard granular activated carbon is not effective in removing high concentrations of perchlorate from groundwater.

To enhance granular activated carbon's ability to remove perchlorate from groundwater, the carbon can be "tailored" by coating the surface with a thin layer of a surface-active substance. Since these substances have an abundance of positive charges, the "tailored carbon" can remove much more perchlorate from groundwater than standard granular activated carbon.

Proven Process

Standard granular activated carbon is approved for treating drinking water throughout the United States. MADEP has also approved standard granular activated carbon for removal of perchlorate from groundwater for studies performed at Camp Edwards in 2003.

Camp Edwards 2003 Activated Carbon Test

Studies at Camp Edwards

The Impact Area Groundwater Study Program commissioned a series of studies to determine the ability of standard and tailored granular activated carbon to remove perchlorate from groundwater to the EPA-approved detection levels used at Camp Edwards (0.35 ppb).

Laboratory studies included Rapid Small Scale Column Tests, which are widely used to determine how well a treatment medium can remove contaminants. These studies used both standard and tailored granular activated carbons to determine the ability of each to remove perchlorate. Results showed tailored carbon removes perchlorate from groundwater up to eight times better than standard granular activated carbon, but its ability to remove explosives was significantly reduced.

A field-scale study to test tailored granular activated carbon is underway to determine if this medium can treat perchlorate to levels below the 0.35 ppb detection level. The study will be completed in summer 2004. Results from this evaluation will help determine the most effective way to remove perchlorate and explosives from groundwater at Camp Edwards.

How It Works

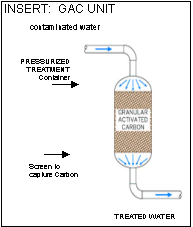

Granular activated carbon removes contaminants, such as explosives and perchlorate, by a process called "adsorption." As contaminated water flows over the activated carbon granules contaminants adhere to the many surface areas on each grain of carbon.

Granular activated carbon removes contaminants, such as explosives and perchlorate, by a process called "adsorption." As contaminated water flows over the activated carbon granules contaminants adhere to the many surface areas on each grain of carbon.

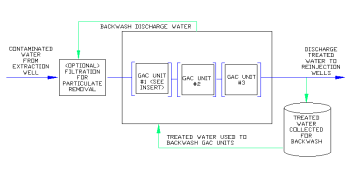

The granular activated carbon systems proposed for use at Camp Edwards would be designed to have contaminated groundwater, extracted from the aquifer, flow through a series of containers or a "treatment train." The treatment train would include containers filled with standard granular activated carbon to remove explosives and some perchlorate, along with containers filled with "tailored" granular activated carbon specifically designed to remove perchlorate. It also could include a final granular activated carbon vessel to ensure that all contaminants would be captured.

The number of containers and type of granular activated carbon used in each treatment train is based on factors including the amount of perchlorate and explosives in groundwater, the amount of competing contaminants, such as nitrates, and the amount of time the water is in the container.

Following treatment, the water is discharged back into the aquifer by reinjection wells. Treated water is sampled frequently to confirm contaminants are being removed.

Over time, the carbon grains may become packed, requiring them to be back-washed. This is done by running clean water backwards through the system to flush out the small particles. The water then is retreated.

In addition, perchlorate and explosives eventually will saturate the granular activated carbon in the containers, requiring it to be replaced with new carbon. Based on the concentrations of perchlorate and explosives being treated at Camp Edwards, carbons used there are expected to have a long operating life.

Used carbons will be treated and/or disposed of in accordance with environmental regulations.

|