What is Thermal Desorption

Spring 2004 Fact Sheet 2004-02

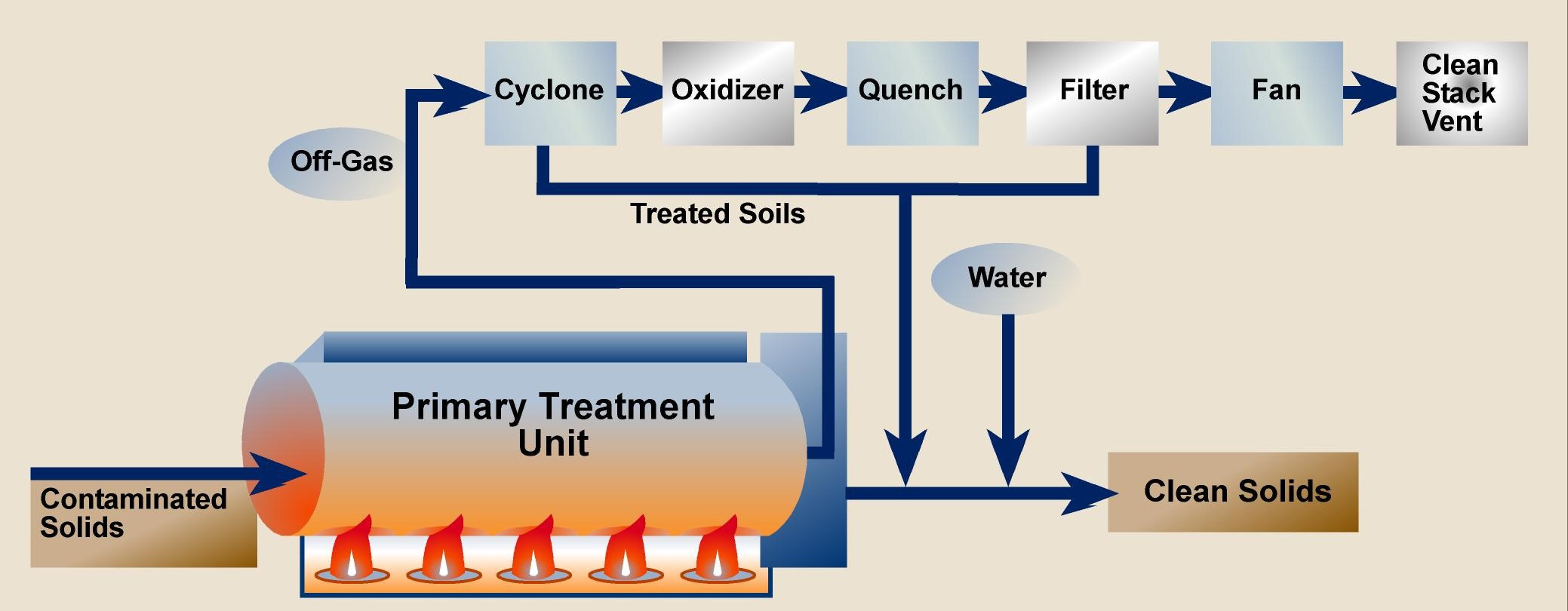

Thermal Desorption is a process used to remove

contaminants from the soil. Temperatures between 500

to 1,100 degrees Fahrenheit (°F) are used to physically

separate moisture and contaminants from the soil.

The exhaust created by this process is collected by an air

pollution control system and heated to temperatures of

approximately 2000°F to destroy the contaminants. The

exhaust is then filtered to remove any remaining dust

particles from the air stream.

Cleaned soil and air are discharged from the

treatment system. Tests on the soil treated by Thermal

Desorption systems typically show a reduction in

contamination to below detectable concentrations. Soil

not treated to acceptable levels is returned to the system

and retreated to achieve required cleanup parameters.

How it Works

The Thermal Desorption system uses heat to separate

contaminants from the soil and then thermally destroys them.

Once rocks and other debris are removed, the soil is fed into

the primary treatment unit. Inside this rotating drum, soil is

heated to between 500 and 1,100°F (775°F is the optimum

temperature for soils at Camp Edwards.) These temperatures dry

the soil, burn off any organic material and drive off contaminants

from the soil, so that they are caught in the exhaust or off-gas.

The continuous tumbling ensures all of the soil is exposed to the

heat for the appropriate time period.

While contaminants are captured in the off-gas, treated soil is

discharged from the primary treatment unit and rehydrated with

clean water to reduce the soil temperature and control dust

emissions.

Treatment of the contaminants continues as the off-gas flows

through the air pollution control system. As it spins through the

cyclone, the soil particles caught in the off-gas are removed

before the off-gas moves into the thermal oxidizer. Using

temperatures of up to 2,000°F the oxidizer destroys any

remaining contaminants, transforming them into nitrogen, water

and carbon dioxide.

In the quench or cooling chamber, clean water is used to cool

the off-gas to a temperature that can be handled by the filtering

system.

The air pollution control system then uses air filters to pull any

remaining treated particles of soil out of the air. A sonic pulse is

used to periodically disengage the collected particles from the

filter and deposit them in the treated soil stream. The filtered offgas

is then discharged.

An air permit, issued by the Massachusetts Department of

Environmental Protection will ensure all emissions meet state requirements.

Discharged soil is sampled to confirm that treatment is

effective. Once sample results confirm that cleanup goals have

been met, soil cleaned through this process can be used for fill in

site restoration.

Proven Process

The Thermal Desorption system has been proven to

successfully treat soil contaminated by explosives

chemicals similar to those found at Camp Edwards. In a

similar use at the Kansas Army Ammunition Plant, the

Thermal Desorption system removed explosives

chemicals, including RDX, HMX and TNT to levels below

what can be detected by approved U.S. Environmental

Protection Agency (EPA) laboratory methods. Similar

results were seen at the Iowa Army Ammunition Plant.

Treatability Study for Camp Edwards

To address soil contamination at Camp Edwards, a a

Treatability Study was conducted to determine the ability

of the Thermal Desorption system to remove perchlorate

from soil. Perchlorate is a water- soluble salt, used as an

oxidizer in munitions and solid fuels for rockets and

missiles. It also is used in, fireworks, safety flares, airbags

and other items. It has been found in soil and

groundwater at Camp Edwards.

The study conclusively verified that Thermal

Desorption successfully treated perchlorate to levels

below what can be detected using approved EPA

laboratory methods.

|